High-quality SLS 3D Printing Service

Tailored rapid prototyping and series production

SLS (Selective Laser Sintering) is an advanced 3D printing technology that uses a high-power laser to selectively fuse layers of fine thermoplastic powder into solid, functional parts. The process builds objects layer by layer from a digital 3D model, producing components with excellent mechanical properties and dimensional accuracy.

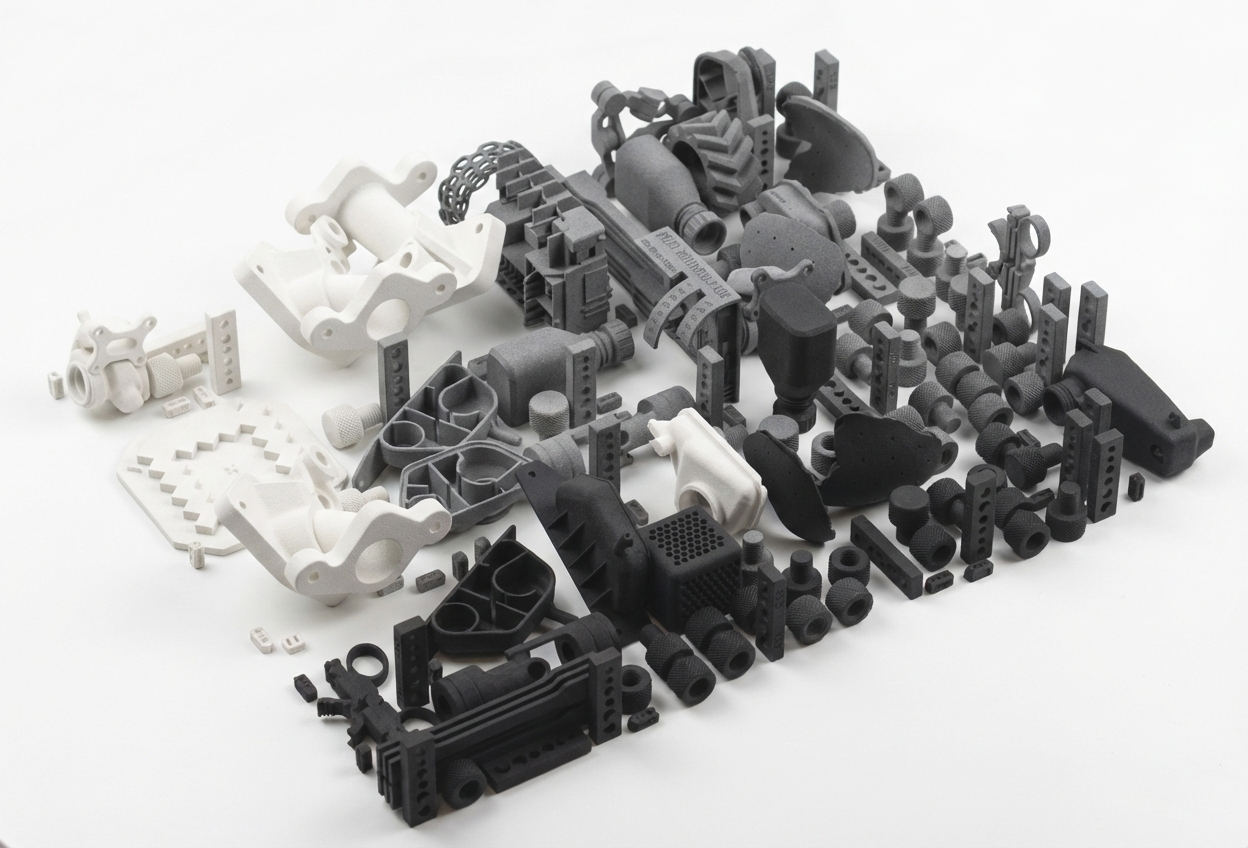

From prototypes to mass production, our SLS 3D printing service combines speed, cost efficiency, and exceptional quality, with a broad material portfolio and the flexibility to support niche materials to match customer-specific needs.

Benefits of SLS 3D printing

- Design freedom: Unlike other additive manufacturing methods, SLS does not require support structures. The surrounding powder itself supports overhangs and complex geometries during printing, enabling the fabrication of intricate features such as internal channels, interlocking assemblies, and moving parts.

- Superior mechanical properties: Printed parts exhibit strong isotropic behavior, making them suitable for functional use.

- Strength and durability: SLS parts are built to last, combining strength and durability for real-world applications.

- Rapid prototyping and production: From prototype to low-volume manufacturing, SLS streamlines development cycles.

- Wide material range: A variety of polymers and engineering powders support diverse performance requirements.

Available materials

TPU

PA12 (Standard & Glass-Filled)

PA11 (Natural & Carbon-Filled)

Polypropylene (PP)

Selective Laser Sintering applications

SLS is widely used across industries for producing functional prototypes, structural components, tooling, fixtures, enclosures, medium-run production parts, and complex assemblies that would be challenging or impossible with traditional manufacturing.

Typical sectors benefiting from SLS include aerospace, automotive, medical devices, industrial machinery, consumer products, and design-focused applications where precision and performance are essential.

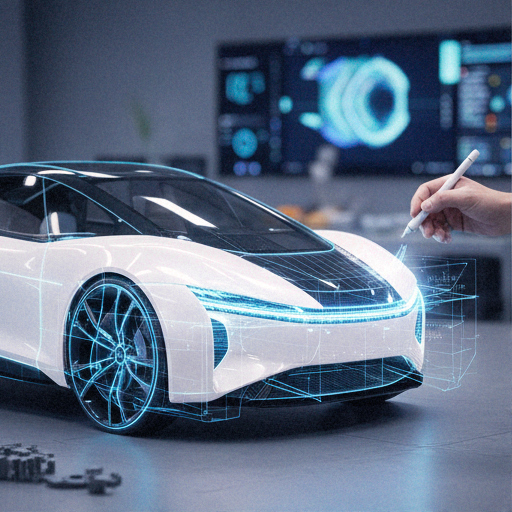

Concept design

SLS 3D printing enables rapid concept design by transforming ideas into physical parts early in the development process. Complex geometries, integrated functions, and lightweight structures can be explored without the constraints of traditional manufacturing, allowing faster validation and iteration from the very first design stages.

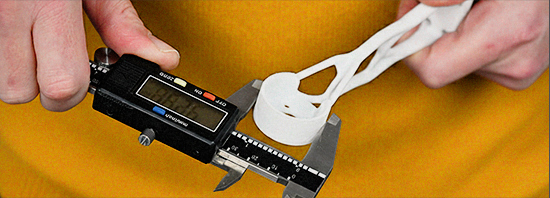

Functional prototypes

SLS technology produces functional prototypes with mechanical properties close to end-use parts. This allows accurate testing of fit, form, and performance under real-world conditions, reducing development risks and accelerating time to market.

Digital Manufacturing

With digital manufacturing, production is driven directly from CAD data, enabling fast turnaround, flexible volumes, and repeatable quality. Design changes can be implemented instantly without tooling, making SLS ideal for agile production, spare parts, and on-demand manufacturing.

Jigs and Fixtures

SLS 3D printing is particularly well suited for producing customized jigs and fixtures. Lightweight, durable, and ergonomically optimized tools can be designed for specific workstations or processes, improving accuracy, reducing operator strain, and lowering production costs.

Contact us to discuss your project needs, material selection, and production feasibility. Benefit from a tailored additive manufacturing solution that elevates both performance and innovation.

Why Spengler

Unlike generic 3D printing services, we offer a fully tailored approach with DFAM-based design support, performance optimization, and process parameters, materials, and finishing adapted to your specific application.

- A detailed assessment of your technical and functional needs, including intended use, mechanical performance, aesthetics, thermal behavior, and regulatory requirements

- Preparation and optimization of the 3D model, including geometry validation, mesh repair, and optimal build orientation

- Production of the part(s) in our facilities, with quality control applied at every stage

- Finishing operations to meet your expectations, starting from the basic yet necessary accurate sandblasting and powder removal, to polishing, coloring, painting, and secondary machining.

- Delivery of parts in the agreed quantities, formats, and timelines, with optional documentation such as material certificates, compliance reports, or dimensional inspection records

Manufacturing SPECS

To ensure optimal part performance, please refer to these industrial SLS specifications for all Spengler manufacturing projects.

- Max build size: 280 x 280 x 280 mm

- Layer thickness: 0.1 mm standard (0.06 mm option available)

- Tolerance: general accuracy ±0.3% (± 0.3 mm)

- Minimum wall thickness: 0.8 mm for consistent mechanical properties

Note: Specific geometry, build stresses, and support strategies may affect final accuracy. Tighter tolerances or flatness requirements require a prototype build and manual review for case-by-case approval.