SurfPro Steam Dyeing (Vapor-based)

Automatic coloring system for SLS and MJF 3D printing

The underlying idea that guided the IntegrAM Group in the development of SurfPro SD (Steam Dyeing) was to create a mass-colouring system with the lowest possible environmental impact and with a flexibility of use in line with the needs of the additive manufacturing industry.

SurfPro SD systems, on the other hand, are based on the use of high-temperature steam to vaporise the colour on objects, ensuring homogeneity and excellent dye penetration, while consuming an extremely small fraction of water and colour compared to immersion systems.

After 24 months of focused research and development, the SurfPRo SD range is now available to the public in two different versions with volumes of 50 and 120 litres.

Submersion Dyeing VS Steam Dyeing: a quick comparison

The benefits of the steam-dyeing technology over the standard immersion systems, whether manual or automatic, are manifold.

Lower ink consumption

Lower water consumption

Uniform, deep, consistent dyeing

Excellent results on different materials

Steam Dyeing technology has achieved excellent results with a wide range of materials, rigid (polyamides) or soft (thermoplastic polyurethanes) and even with the notoriously complicated polypropylene.

The SurfPro Steam Dyeing coloring systems are compatible with:

- HP 3D HR PA 11

- HP 3D HR PA 12 S by Arkema

- HP 3D HR PA 12 by Evonik

- HP 3D HR PA 12 W (White)

- HP 3D HR PA 12 FR by Evonik

- Forward AM Ultrasint® TPU01

- EOS PA 2200

- EOS PA 1101

- 3D Systems PA11 Natural

Tests on new materials can be performed at the request of customers.

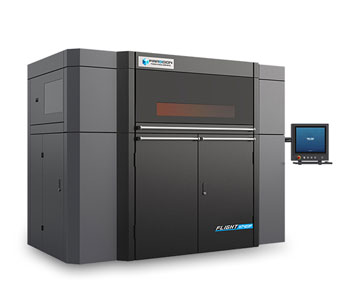

Designed for high-throughput binder jetting and laser sintering 3D printers

HP MJF 5200

EOS P3 Series

Farsoon P403

EOS Formiga

And, of course, many others.

All trademarks, logos and brand names are the property of their respective owners

Why choose the SurfPro Steam Dyeing technology?

Simply put, compared to traditional colouring systems, with a few exceptions based on the same immersion technique that has been used for hundreds of years, the innovative IntegrAM steam dyeing systems boast several advantages.

1) Less water, less colour, same results

Traditional colouring systems use large quantities of water and colour, of which only a small part is transferred to the parts, while all the rest becomes waste to be disposed of. In proportion, SurfPro SD systems consume 1/10 of water and 1/20 of colour compared to conventional systems.

2) Reduced ecological impact, incomparable economic benefits

The logical consequence of point number 1, is the reduction of pollutant waste, reduced consumption of water and the electricity needed to heat it. This makes the SurfPro SD system not only ecologically friendly but also cost-effective to operate.

3) Just one system, multiple colours

One of the most popular colours for the dyeing of 3D printed parts is, without going around it, black. And this is why the IntegrAM Group focused on Extra-Black as the first product in the range to be launched on the market.

But a complete range of colours will be available soon, to cover all clients’ needs. Also, switching from one colour to another is just a matter of minutes!

NO-NONSENSE ENGINEERING

- HMI touch screen for programme and recipe management

- Vibrating vat with lid, suitable for steam and hot air drying

- Boiler for dry saturated steam

- Hot air blower for drying

- Recycling/recovery tank with three-way control valve and electric pump

- Self-supporting pallet frame, plug & play installation

- Colour container

- Dosing station for 1 gel compound and 1 chemical compound, with solenoid valve and flow meter