VibroBLAST Air system

Surface blasting systems for metal additive manufacturing

The VibroBLAST technology is revolutionizing post-processing in metal additive manufacturing. IntegrAm’s cutting-edge automatic sandblasting system delivers unmatched results, combining efficiency and consistency and streamlining metal surface finishing like never before.

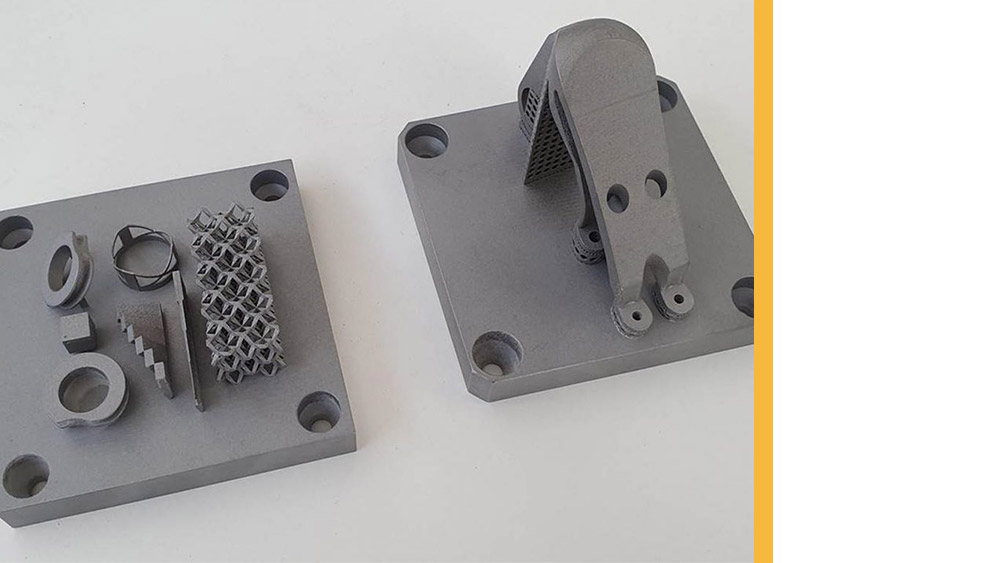

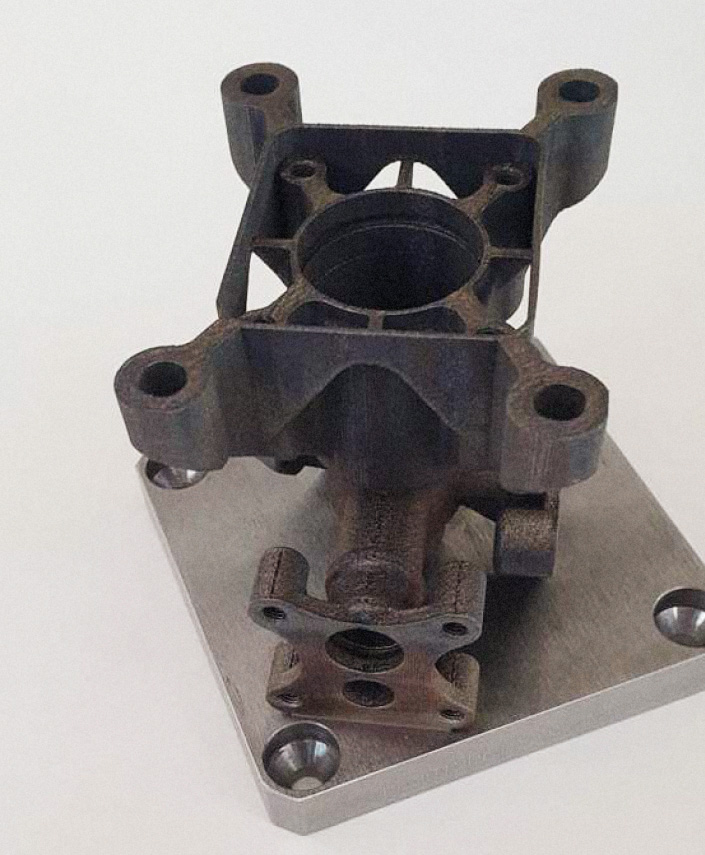

Thanks to a patent pending process that combines sand/shot blasting and vibratory finishing, VibroBLAST Air allows mass-finishing of 3D printed metal parts printed with DMLS, SLM or EBM systems.

See it in action

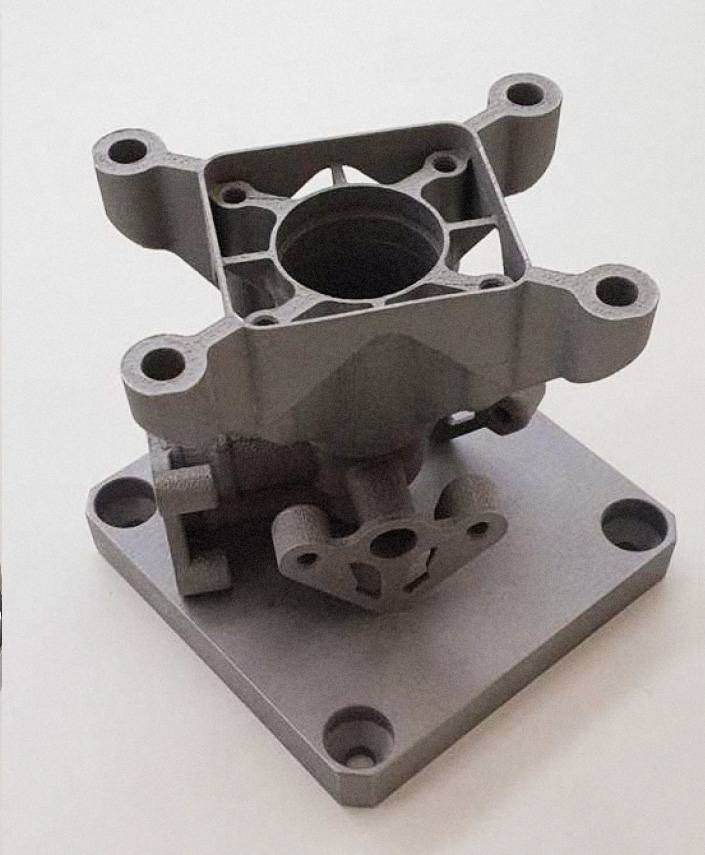

Sandblasted parts, plus their base plate

Bringing true innovation to the sandblasting panorama

How does the VibroBLAST Air system outperform manual and traditional barrel sandblasting tools?

Both systems offer automatic depowdering, but the VibroBLAST stands out by using elastic vibratory media that gently reorient 3D-printed parts, exposing them to blasting nozzles from multiple angles.

As a result, the VibroBLAST Air provides significantly gentler handling of 3D-printed parts compared to traditional rotational blasters, avoiding impacts between parts and allowing batch surface post-processing.

VibroBLAST: surface finishing or surface preparation?

Well, the quick answer is: both! Depending on your rugosity targets, the VibroBLAST system might be the only tool you need.

As a rugosity attenuation tool

Before

After

Advantages

The advantages of the VibroBLAST system are many, both compared to a manual processes, of course, but also compared to automatic systems:

- Homogenous and consinstent sandblasting

- Controlled roughness down to 1.2 microns*

- Fully automatic, programmable process, ideal for batch processing

- Designed to handle even hundreds of parts at the same time, it can also process 3d printed elements still connected to their build plates

- Tested with 3D printed parts made in Inconel 718, Titanium TI64, 17-4 Ph martensitic stainless steel, 304L and 316L austenitic stainless steel

* Results depend on the material to be processed, starting roughness, layer thickness and in general, quality of the 3D print

As a surface preparation tool, to reach mirror-finish results (ultra-low Ra)

On the other hand, many applications require Ras al low as 0,2 or 0,3 microns, and to reach that level of surface smoothness, the SurfPro Microfluid is the perfect tool that will allow you to get to the desired target, after a VibroBLAST cycle.

In thins case, the VibroBLAST system will work as a surface preparation tool with the aim to:

- Make the surface more homogenous by equalising upskin and downskin roughness, for example.

- Quickly and automatically reduce the initial roughness to allow shorter finishing cycles.

- It allows achieving medical-grade surface finishng levels, a goal difficult to attain without proper surface preparation.

VibroBLAST features

(for metal post-processing)

- VBA-DP: 3 sizes available

- Plug and play

- Siemens PLC control: Easy to use, with editable parameters

- Anti-static system

- Single blasting nozzle

- Self-cleaning filters (option)

Super VibroBLAST features

(for metal post-processing)

- For high-productivity environments

- SVBA-DP3: 2 sizes available

- Plug and play

- Siemens PLC control: Easy to use, with editable parameters

- Anti-static system

- Double blasting nozzle

- Triple media vacuum drain

- Self-cleaning filters (option)